Brewster

Description

“The Brewster Process.

(U.S.P. 1,752,477. 1930-)

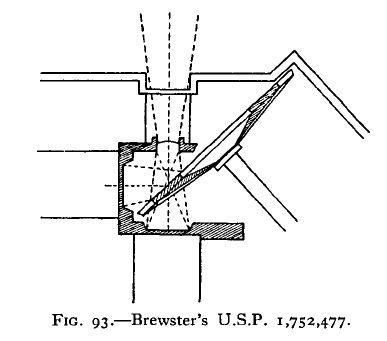

Camera. – P. D. Brewster, an American inventor, who was one of the first to apply the bipack system to colour cinematography, has a number of patents to his credit covering various cameras and printing machines. In E.P. 130,002, a camera is described for the production of two-colour films in which the usual arrangement is adopted of two gates at right angles to each other, and a prism cube with cemented reflecting face half-silvered, and disposed at 450 to the axis of the beam. In U.S.P. 1,752,477, the prism is replaced by a rotating mirror (Fig. 93).

The following description of the latest type of Brewster camera appears in the Photographic Journal (Vol. LXXV, August 1935, p. 455) :

Brewster’s suggestion was that the light should be divided up between three separate negatives, each of which should receive light from the whole of the lens. The way in which that was done was to make use of metallic mirrors, rather like propellers, disposed at right angles to each other. Dr. Spencer (who presided at the meeting of the Royal Photographic Society at which the Brewster process was demonstrated, April 12, 1935) sketched the design on the blackboard, pointing out that if one ” propeller ” was spun round on its axis light would be reflected from the vanes on to the film at right angles to the entering beam, and when the propeller had made one complete revolution the whole of one image would be completed. As, however, the vanes had apertures between them, light would be transmitted at the same time to the rear image. If at an angle to the first propeller a second were placed, the period of revolution of which was so arranged that the two would cross each other’s path when revolving without interfering with each other, as soon as one vane of the first reflector moved out of the way a vane of the second reflector could cross the path just left, and so the image was obtained with one complete revolution of the vane. It would be appreciated what a high precision job it had to be. An absolutely steady picture had to be cast on each of the three frames, which meant that the mirrors must be finely worked surfaces, finely disposed.

In adopting this type of camera Brewster has avoided the defects of bipack. All three negatives will be of maximum definition – a very great advantage indeed. The film shown on the occasion referred to above was admirable for freedom from halation, and for excellent definition of distant detail.

Printing. – The method at present employed by Brewster seems to be as follows: double-coated positive film is printed on one side with the red filter negative, and on the other side with the green filter negative. The development of these is carried to a low gamma, and exposure is light. These two images are converted into silver iodide and dyed with basic dyes; a process originally invented by A. Traube (D.R.P. 187,289, 1905). The side printed with the red filter negative is dye-toned subtractive primary blue, the side printed with the green filter negative is dye-toned subtractive primary magenta. The remaining yellow component is printed on top of the dye-toned image by imbibition from a relief matrix film made in the customary manner by developing with a tanning developer such as pyro, or pyro and adurol. The unhardened gelatine is dissolved away with hot water after development. Such a method is elaborate and must be somewhat difficult to control both as to registration and colour balance.

The following description has recently been published:

The red and blue negatives are printed on to two sides of a double-coated positive film. The images are bleached out to invisible silver iodide images, and are toned with basic dyes, to pink and blue. The pink side is then coated with another emulsion, which is exposed to the green negative record and correspondingly tinted by a new process which is not being divulged until further patents have been granted. Basic dyes are said to give an advantage over the acid dyes used by Technicolor.

Remarks. – This printing system would not prove very practicable for commercial work, and it is difficult to see how such an elaborate processing sequence could compete with Gasparcolor or Technicolor.

(Klein, Adrian Bernhard = Cornwell-Clyne (1940): Colour Cinematography. Boston: American Photographic Pub. Co.. 2nd revised edition, pp. 225-227.)

Galleries Open all Galleries ▼

Original Technical Papers and Primary Sources

Brewster, P.D.; Miller, Palmer (1931): Three Color Subtractive Cinematography. In: Journal of the Society of Motion Picture Engineers, Jan. 1931, pp. 49-56. View Quote

Secondary Sources

Brown, Simon (2012): Technical Appendix. In: Sarah Street: Colour Films in Britain. The Negotiation of Innovation 1900-55. Basingstoke, Hampshire: Palgrave Macmillan, pp. 259-287, on pp. 264-265. View Quote

Cleveland, David; Pritchard, Brian (2015): How Films were Made and Shown. Some Aspects of the Technical Side of Motion Picture Film 1895–2015. Manningtree, Essex: David Cleveland, on pp. 211–212. View Quote

Klein, Adrian Bernhard = Cornwell-Clyne (1940): Colour Cinematography. Boston: American Photographic Pub. Co., 2nd revised edition, pp. 225-227. View Quote

Ryan, Roderick T. (1977): A History of Motion Picture Color Technology. London: Focal Press, pp. 72-75. View Quote

Street, Sarah (2012): Colour Films in Britain. The Negotiation of Innovation 1900-55. Basingstoke, Hampshire: Palgrave Macmillan, on p. 45. View Quote

Films

According to Simon Brown, Technical Appendix: Brewstercolor. In: Street, Sarah (2012): Colour Films in Britain. The Negotiation of Innovation 1900-55. Basingstoke, Hampshire: Palgrave Macmillan:

Barnum was Wrong (1930)

Mendelssohn’s Spring Song (1931)

Let’s Look at London (1935)1

See How they Won (1935)

1 Street, Sarah (2012): Colour Films in Britain. The Negotiation of Innovation 1900-55. Basingstoke, Hampshire: Palgrave Macmillan, on p. 45. View Quote

Downloads

Patents

E.P. 450,673 (Brewster, Percy Douglas; filed Oct. 20, 1934; granted July 20, 1936)

Download PDFU.S.P. 2,070,222 (Brewster, Percy Douglas; filed June 5, 1933; granted Feb. 9, 1937)

Download PDF